Liuan, Anhui Feb 4, 2026 (Issuewire.com) - Fundamentals of Automatic Leak Testing: A Comprehensive Buyers Guide

In the rapidly evolving landscape of high-end manufacturing, precision is no longer a luxury but a fundamental requirement for operational viability. As industries strive for zero-defect production, the role of a Reliable Automatic Leak Testing Machine Supplier has become pivotal in ensuring product integrity and safety. Automatic leak testing machines are sophisticated systems designed to detect micro-leaks in components using various tracer gases, most notably helium, within a controlled vacuum environment. Unlike manual inspection, these automated systems integrate seamlessly into production lines, utilizing robotic handling and advanced sensors to perform non-destructive testing at high speeds. The implementation of such technology triggers a positive chain reaction throughout the manufacturing process: it eliminates human error, significantly reduces cycle times, and provides granular data for quality traceability. By catching defects at the earliest possible stage, these machines prevent costly recalls and safeguard a brand's reputation, ultimately enhancing the overall efficiency and profitability of the smart factory ecosystem.

For procurement professionals and technical directors, understanding the core mechanisms of leak detection is essential before making a capital investment. This guide outlines the four critical pillars of automatic leak testing technology that define modern industrial standards.

The Principle of Helium Mass Spectrometry

Most high-precision automatic leak testing machines utilize helium as a tracer gas. Helium is non-toxic, non-flammable, and has a small molecular size, allowing it to pass through the tiniest fissures. The machine works by evacuating a vacuum chamber containing the test piece, then sensing any helium molecules that escape from the pressurized component using a mass spectrometer. This method is capable of detecting leaks as small as 1x10^-12 mbar.l/s, offering a level of sensitivity that water-dunk or pressure-decay methods simply cannot match.

Automation and System Integration

A truly "automatic" system goes beyond the testing unit itself. It encompasses the automated loading and unloading mechanisms, precise sealing fixtures, and the software logic that governs the test cycle. Modern systems are designed to interface with Factory Management Systems (MES), allowing for real-time monitoring and automated "pass/fail" sorting. This integration ensures that the testing phase is not a bottleneck but a synchronized part of the high-speed production flow.

Calibration and Peak Tracking

More On Newsinterestcorp ::

- Best Source for Segmented - Verified B2B Email Lists in the Gulf: Saudi Arabia, UAE, and Beyond

- Taichuan debuted at the International Security Fair ESS+2025, connecting new global opportunities with OEM capabilities

- A Story of Redemption, Regret, and Unexpected Grace

- Jami Erskine, Recognized by BestAgents.us as a 2025 Top Agent

- pnjntrzfok

Accuracy is only as good as the systems last calibration. Advanced machines now feature automatic peak tracking and internal calibration standards. This technology compensates for environmental variables such as temperature fluctuations or background gas levels. By automatically adjusting the sensor's focus to the "peak" of the helium signal, the machine maintains its sensitivity and reliability over thousands of cycles without requiring manual intervention from an engineer.

Data Digitalization and Traceability

In the era of Industry 4.0, a leak tester is also a data generator. Every test result, including leak rates, vacuum levels, and timestamps, is recorded digitally. This creates a "digital twin" of the quality control process, enabling manufacturers to perform trend analysis and identify potential upstream tooling issues before they lead to mass defects.

The Risks of Substandard Equipment and the Imperative of Innovation

The market for leak detection equipment is diverse, but the cost of choosing a substandard system can be catastrophic. Low-quality leak testing machines often suffer from "signal drift," inconsistent sealing, and high maintenance requirements. If a defective component passes through an unreliable machinea "false negative"the downstream consequences include product failures in the field, potential safety hazards for end-users, and massive financial liabilities due to recalls. Furthermore, frequent downtime caused by equipment failure disrupts the entire production schedule, eroding the ROI of the manufacturing line.

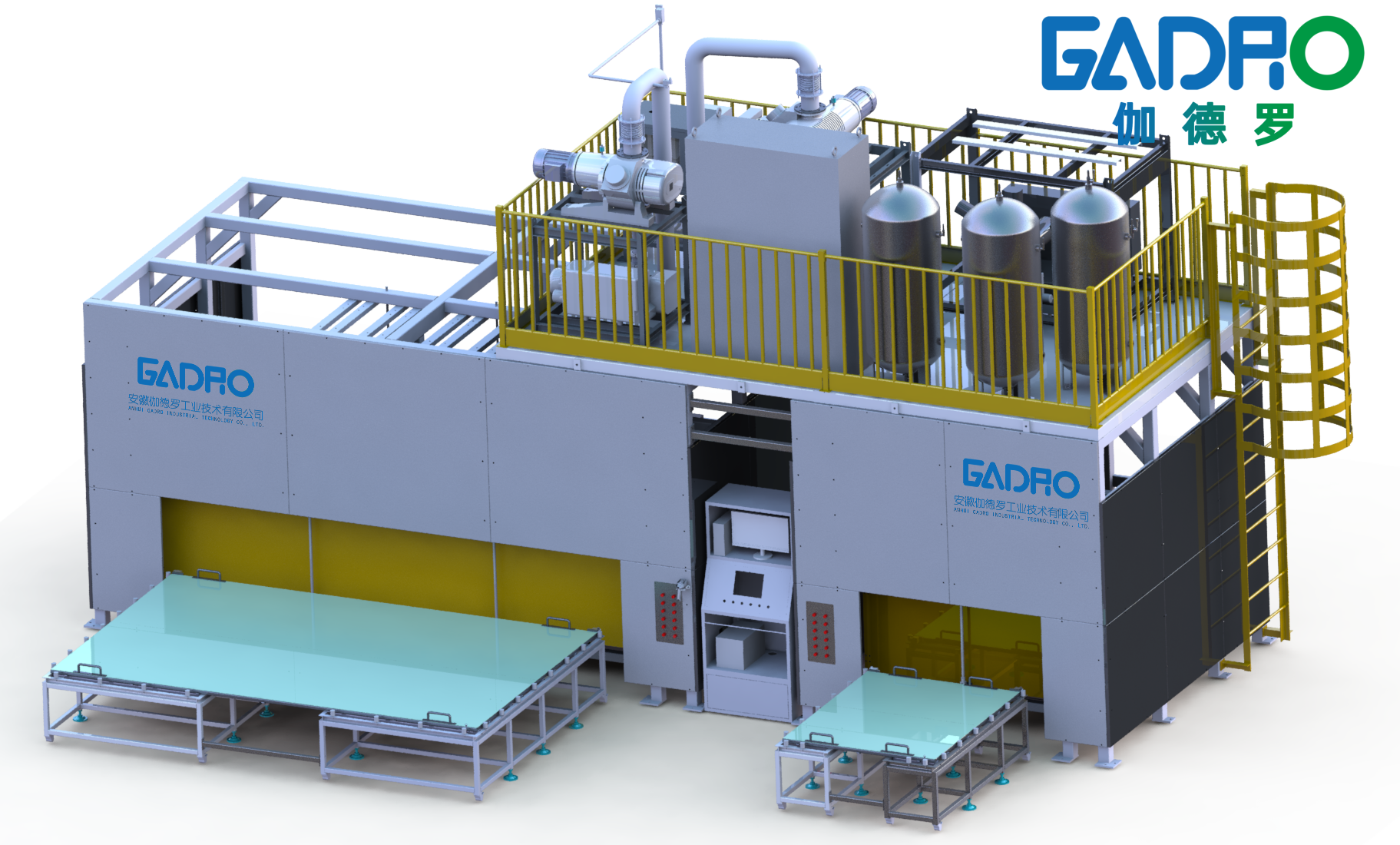

To mitigate these risks, Anhui Gadro Industrial Technology Co., Ltd. has focused its research and development on technical innovations that ensure long-term stability. The core competitiveness of GadroTech lies in its holistic approach to vacuum technology. Unlike suppliers who merely assemble parts, Gadro develops integrated technical systems. Their equipment features enhanced vacuum chamber designs that minimize "noise" and background interference, ensuring that the detected signal is genuine.

Moreover, Gadros innovation extends to the "Smart Factory" level. Their systems are built on an industrial Internet big data platform, which allows for predictive maintenance. By analyzing the performance metrics of the leak detector, the system can alert operators to replace seals or service vacuum pumps before a failure occurs. This proactive technical philosophy transforms leak detection from a passive gatekeeper into an active optimizer of the manufacturing process.

Strategic Advantages and Industry Applications of GadroTech Solutions

Anhui Gadro Industrial Technology Co., Ltd. has established itself as a leading force in the vacuum leak detection sector through a combination of technical depth and customized service. The company's expertise is not limited to standalone devices but extends to comprehensive automated production lines tailored for specific industrial needs.

Core Advantages of GadroTech:

- Nearly Ten Years of Professional Experience: With a long history in the Chinese market, the company understands the nuances of vacuum physics and industrial automation.

- Holistic Solutions: From single-unit helium leak detectors to full-scale digital smart factory planning, Gadro provides a vertical range of services.

- Responsive Support: The company maintains dedicated pre-sales and after-sales teams to ensure that technical consultations and field services are handled with high efficiency.

Primary Application Scenarios:

- New Energy Vehicles (NEV): Testing the integrity of battery packs, cooling plates, and motor housings where even a microscopic leak could lead to thermal runaway.

- HVAC and Refrigeration: Ensuring the hermetic sealing of compressors and heat exchangers to prevent refrigerant leakage and environmental impact.

- Power Distribution: Testing SF6 insulated switchgear and high-voltage components to maintain grid stability.

- Aerospace and Vacuum Industry: Providing high-vacuum chamber systems for components that operate in extreme environments.

The global manufacturing trend is moving decisively toward intelligent, green, and high-precision production. As regulations regarding environmental protection and product safety become more stringent, the demand for high-sensitivity helium leak detection is projected to grow exponentially. GadroTech is positioned at the forefront of this trend, continuously refining its automatic peak tracking and calibration functions to meet the demands of the next generation of industrial manufacturing.

By choosing a partner focused on "Premium Products" and integrated digital systems, manufacturers can ensure that their quality control processes are future-proofed against the challenges of 2026 and beyond.

For more information on advanced leak detection solutions, visit the official website: https://www.gadrodetection.com/

Source :Anhui Gadro Industrial Technology Co., Ltd.

This article was originally published by IssueWire. Read the original article here.